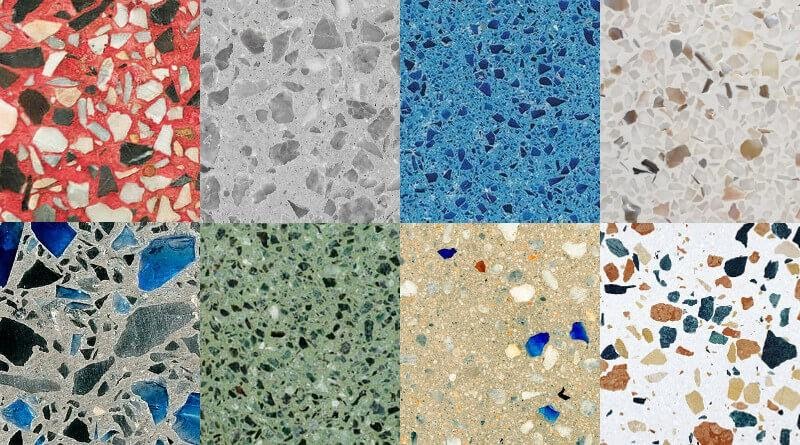

A lot of information is circulating on terrazzo tiles from across the world. The answer is simple because the materials are describable to those who have seen them at least once. The terrazzo tiles are capable of creating unique finishes to beautify the house. Moreover, the definition for terrazzo tiles is that of a set of composite materials made from chips of marbles, stones, granite, quartz, shell, and other precious stones.

This combination of items is laid within a concrete or resin base and sliced into standard sizes that fit different parts of the home or office. At the same time, some of the places where you can apply terrazzo tiles include the floor, base, walls, treads, outdoor compound, walkway, stair treads, countertops, and other areas. Meanwhile, the base material, such as the concrete and epoxy, also doubles as the binder.

While installing the terrazzo tiles, you may have to divide them into small sections with metal strips. At the same time, the color may add to the transition. Also, each of the terrazzo tiles may carry different patterns, logos or be a piece is a puzzle image. This arrangement is essentially valuable for preventing crack as a mitigation strategy. At the same time, the divider strips can be made out of aluminum that is for epoxy terrazzo tiles only. Alternatively, the divider can be made from zinc, plastic, stainless steel, or brass.

The Basic Types of Terrazzo Tiles Systems

Several terrazzo tiles systems exist in the industry, including the cementitious and the thin-set epoxy resin systems.

- Thin-Set Terrazzo Systems

The thin-set of terrazzo tiles comprises an epoxy resin or a compound of Polyacrylate to make the matrix. At the same time, it has a higher impact resistance than cement and allows for vapor transmission.

The installation of the thin-set terrazzo tiles systems is similar to the traditional monolithic terrazzo. However, it has a minimum thickness of about 3-quarter inches of the latter, under ideal conditions. Furthermore, the epoxy resin matrix holds the terrazzo inside two resin components while bonding directly to the concrete slab. Now, the epoxy terrazzo tiles are the most standard system that is employed in commercial structures construction.

One of the significant benefits of choosing the thin-set terrazzo tiles, especially over the cementitious terrazzo, is its endless colour selection. These epoxy terrazzo tiles systems can also comprise exotic aggregates as a mirror, mother of pearl, and pearl aggregates. Also, it does not allow vapour to pass through it while enhancing the moisture mitigation products when you install it. However, one disadvantage of using thin-set terrazzo tiles is that it is more suitable for interior and not exterior applications.

Cementitious Terrazzo Tiles Systems

A cementitious system comprises monolithic terrazzo with half-inch terrazzo topping joined with the existing or new concrete slab. This prepared panel can then be poured into the bonded metal divider strips in L-shape. There are two primary forms of cementitious terrazzo system: the sand cushion terrazzo and the rustic terrazzo, also known as the washed terrazzo.

Sand Cushion Terrazzo Tiles. This type is formed when the terrazzo mixture is poured over a reinforced wire mud bed of about 2.5 to 3 inches. This low slump of a mix of sand and cement mixture is the desired shape that the contractors erect. At the same time, the mud bed still remains soft in a standard straight metal divider strip. This component is also embedded in the mud bed wherever there is a joint or color change.

Rustic Terrazzo or Washed Terrazzo Tiles. This type comprises an exterior application through a slip-resistant texture finish. It is called washed terrazzo because while grinding and polishing the finish, the process involves washing away some of the cement and exposing the marble, quartz or granite aggregate in the mixture. Rustic terrazzo tiles can be installed as in a bonded or monolithic mud bed application.

Installation of Cementitious Terrazzo Tiles

The process of installing cementitious and epoxy terrazzo tiles is quite different from the binder. At the same time, this process requires a separate installation concerning the makeup system. Since the cementitious terrazzo is a mixture of marble aggregate and white or grey cement. The coloring component is also a mix of iron oxide and other materials with water. Afterward, you can then pout it within the specified panel and boosted it to the desired height.

The aggregate is sprinkled on the floor with a set roller across the floor with embedded marble chips. On the other hand, the marble chips worked with excess cement with water on top of it and were removed afterward. You can also repeat the rolling process with differently weighted rollers in a way that extracts excess water and cement from the floor. After this process, you can do light troweling while allowing the foot to cure for a couple of days.

Installation of Epoxy Terrazzo Tiles

The installation process of Epoxy terrazzo requires less labour and extensive skills as in a cementitious system in a simple form; it comprises of two parts. The first is a base colour, while the other is the hardener in a 5: 1 ratio. When you mix the two parts together with filler powder from marble dust, you obtain an aggregate. You can then pour both the total and the epoxy terrazzo on the desired floor and place them to the desired height with hand trowels.

Grinding, Grouting and Polishing Terrazzo Tiles

The grinding process for both the cementitious terrazzo and the epoxy terrazzo tiles take similar procedures except initial rough grinding. Epoxy terrazzo requires such coarse grinding and the application of a vacuum system that collects the dust. On the other hand, cement terrazzo requires wet ground by creating a grinding slurry. You keep grinding the rough ground until the plastic or metal divider strips are revealed.

Following the grinding process, you can also grout both systems, and the installer matches binder materials on mixing. The mixed material fills the available voids and pinholes, and then you can polish the floor after curing the grout. Typical polishing is done in a wet stem with a finish level between 120 and 3000 grit in both significant terrazzo tile production types.

Conclusion

On a final note, this comprehensive guide analyses the two significant types of terrazzo tiles and the process of producing and installing them. Hopefully, you can find the beauty that you imagined through these materials.